Happy New Year!

We usher in the new year with its first publication, "Winter 2017 Issue." We cover a variety of topics, among them:

A look at the versatile Crane Bay® Yellowfin Tuna Strips - combining quality with convenience

Interested in the hot food trends for 2017??? - you'll find them here

Statistics show shrimp exports from Vietnam soar to the U.S.

Do you enjoy Japanese Nabe or Hot Pots - here are a few delicious alternatives that promise both health and beauty benefits

Read about the forecast of Chilean Salmon post algal bloom and one positive outcome of that crisis

Our blog comes from our Corporate Chef, Kevin Lee - see what he has to say about his new role and what it can mean for you

As we step into 2017, please accept our warmest wishes for a happy, healthy and prosperous new year. We hope you enjoy this issue and as always, thank you for your continued support.

Best regards,

DNI Group, LLC

PRODUCT SPOTLIGHT: Crane Bay® Yellowfin Tuna Strips

Let's take a look at Crane Bay® Sashimi Grade Yellowfin Tuna Strips. Hand cut from #1+ and #1 grade quality tuna, it's a quick and convenient way for your customers to put delicious sashimi grade tuna tuna on their menus.

Perhaps you have noticed that restaurants of all kinds are now featuring raw tuna selections somewhere on their menus. For your customers who are adding Yellowfin tuna to their menus, Crane Bay® Sashimi Grade Yellowfin Tuna Strips is the solution. This high quality tuna delivers great flavor, value, savings and convenience to any food service operator.

• Strips are the perfect length to use in sushi rolls or spring rolls

• Dice the strips and use in your favorite Poke recipe

• Cut the strips in half and add vegetables for a delicious hand roll

• Chop the strips, season and make tuna lettuce cups or tuna tacos

Here are some FAQ’s we have received that may provide answers to your own questions about Tuna Strips...take

Where do the tuna strips come from?

All the Crane Bay® tuna is line-caught in Indonesia. We use only #1+ and #1 quality whole fish and it is always HAND-CUT. Strips are the parts of the fresh fish remaining after the saku and loins have been cut. Because the specifications for the shape of those cuts are so precise, a lot of good meat is shaved off. Only that random sized sashimi meat is then hand cut into “Strips”.

Is a machine used to cut the tuna?

No. All the tuna is hand cut regardless of its final use. Hand cut is a better option for tuna than machine cut. If the meat is ground or processed in a machine, it is imperative that the machine be constantly cleaned and sanitized to avoid any risk of pathogen contamination. Hand cutting the tuna reduces that risk.

How are the Tuna Strips packaged?

The Strips are packed in 1 pound bags x 11 bags x 2 inner boxes for a total of 22 bags per case.

PRODUCT SPECIFICATIONS:

RECIPE IDEA: Crane Bay® Yellowfin Tuna Strip Poke Nachos

Poke Nachos is a vibrant way to showcase Crane Bay®Yellowfin Tuna Strips on any appetizer menu. Cut thestrips and marinate in sesame oil, garlic and soy sauce. Addchopped avocado, cilantro, sliced Serrano peppers, green onion,sesame seeds and julienned nori. Scatter the mixture over crispy won tons and serve with sweet soy and Sriracha aioli.

NEW YEAR MESSAGE FROM THE PRESIDENT

I am personally grateful to each one of our customers for their support throughout 2016. We know there are many seafood suppliers in the market and we are deeply appreciative for your continued loyalty. I hope we have made a positive contribution to the success of your goals in 2016. As always, it is our intention to be your trustworthy business partner focusing on a win-win outcome for the long term.

As we enter the new year, please know that DNI Group will continue to offer high quality sashimi grade seafood and authentic Japanese appetizers. It remains clear that a constant, reliable supply chain is the foundation for a successful seafood business and this continues to be a priority at our company. Maintaining that steady, stable supply chain allows us to provide you with quality products, accurate service, reliable inventory and timely delivery.

We are looking forward to starting anew in 2017. Through “kaizen” or “positive change on a regular basis”, our goal is to continue to evaluate and improve our business in whatever ways we can. We have added new staff to strengthen our customer relations department. Our operations team is researching potential new products that will fit into “our family” and meet your requests for specific items. And lastly, after over 10 years, we are developing a new logo which we believe will better communicate our identity in the seafood industry. This promises to be a very exciting year at DNI Group and we look forward to sharing it with you.

In closing, on behalf of myself and all the staff here, please accept our best wishes for a peaceful, happy and prosperous 2017. We look forward to continued mutual success in the new year.

Warm Regards,

DNI Group

Devan Nielsen, President

FOOD TRENDS: Top Food Trends for 2017

Consumers next year may be eating chocolate at breakfast, sardines with lunch

and goat for dinner, according to a new list of culinary trend predictions by Sterling-Rice

Group.

With nutrition, sustainability and authenticity topping the list of priorities, consumers are seeking to rediscover traditional cooking methods and explore global cuisines - and restaurants and packaged food companies are taking note, said Liz Moskow, culinary director at Sterling-Rice Group. “Simply put, engaging with food is a conduit to engaging with the world,” she said.

SHRIMP REPORT: Vietnam Shrimp Exports to U.S. Soar 17.2%

The U.S. accounted for 23% of Vietnam total shrimp imports in nine months through September 8

Vietnamese shrimp exports to the United States grew consistently every month through September, with the exception of June, which saw shipments decrease by 1.5 percent compared with the year prior, according to the Vietnam Association of Seafood Exporters and Producers (VASEP).

In the third quarter of the year, shrimp exports to the United States reached $221.3 million, up 51 percent compared with the second quarter of the year, and up 17.2 percent compared with the same period a year earlier.

Through September, shrimp exports to the US Market reached $ 520.2 million, up 15.2 percent over the same period in 2016.

The United States is the largest shrimp importer of Vietnam, accounting for 23 percent of total shrimp exports Vietnam in the first nine months of the year.

-Taken from www.Intrafish.com, December, 2016

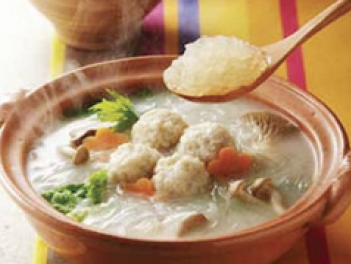

JAPANESE CULTURE: Hotpots for Health and Beauty

Soymilk, Collagen and Tomato are featured in new varieties of Nabe

No dish is better suited to Japan’s cold winter nights than the nabe (Nah-Beh in Japanese), or hotpot. Sitting with friends and family around a simmering pot full of vegetables, fish and meat has been a favorite wintertime activity of the Japanese for generations. Boiling softens the fibers in the vegetables, making it easier to gobble up large, healthy portions of the nutrients they contain, while the bubbling soup soaks up vitamins and minerals from the meat and fish and is full of nutritious goodness. The combination of piping hot food and lively conversation warms both body and soul and makes the nabe perfect for get-togethers with friends and family

Collagen nabe

The Anti-Aging Hotpot

The most popular soup bases have traditionally consisted of kombu (kelp) stock with soy sauce, salt, or miso, but there are no hard and fast rules, and different kinds of nabe exist from region to region and from family to family. Enjoying a huge wave of popularity at the moment are several new types of nabe with soups containing collagen, soymilk, or tomatoes. Many of the new varieties promise health and beauty benefits as well as a tasty meal. Initially popular mostly with women, the health-giving benefits of these new dishes-which are purported to give a much-needed boost of energy to tired bodies and minds-have made the new nabe popular with men as well.

Tomato nabe

The Birth of the Tomato Hotpot

The tomato nabe provides a new, vegetable-rich twist on the traditional dish. Often seasoned Italian-style with olive oil and white wine, the ingredients of tomato nabe generally include shrimp, squid, wiener sausages, and mushrooms. The base of the soup is made from crushed tomatoes, providing a unique and delicious combination of sweetness and rich, full-bodied flavor. Adding rice at the end produces a dish similar to ketchup-flavored chicken rice, while the use of such varied ingredients mirrors some of the combinations used in pasta or pizza dishes. Tomato hotpots can also be accented with Japanese-style seasonings.

Soymilk nabe

Healthy Soymilk Nabe

Another healthy option proving a firm favorite in the nation’s restaurants and homes is the soymilk nabe, which combines the delicate, subtle flavor of soymilk with the richness of vegetables, chicken, and other ingredients. Many people like to add miso paste or sesame for an extra twist. It is the freedom of hotpots that makes them so much fun. There is no need to follow a recipe. You can add anything you want, and use whatever flavoring or stock takes your fancy. The culture of nabe is all about enjoying a delicious mix of different ingredients. It is a dish that never stops evolving.

-Taken from Trends in Japan

SALMON UPDATE: Chilean Salmon Sector May See Reversal of Fortunes

After an eight-year roller coaster ride, the Chilean salmon sector has returned to profitability and it looks likely to stay that way, according to Rabobank's Gorjan Nikolik.

Since the infectious salmon anaemia(ISA) crisis in 2008 the Chilean industry has experienced a challenging period with volatile supply, rising costs of production and financial losses, but this dynamic has reversed recently and Chilean farmers have returned to profitability, according to Gorjan Nikolik, senior analyst at Rabobank.

The main reasons for return to profitability, and the expectation it will stay there, center around predictions of strong harvest growth in the coming years, as well as vastly reduced costs and higher prices, said the analyst in a recent post. Our expectation is that this period of profitability will last,” he said.

By the end of 2018, the Chilean salmon farming industry expects to recover the 100,000 metric tons lost as a result of the algae bloom in the first quarter of 2016, and will achieve “considerable growth” in the foreseeable future, he said.

The algae destroyed 100,0000 metric tons of salmon production capacity - approximately 60,000 metric tons were supposed to be harvested in 2016 and approximately 40,000 in 2017. “The expectation is that supply will expand only slightly in 2017, while considerable growth will be achieved in 2018,” said Nikoli.

One reason is that initially smolt release was expected to decline relative to 2014 and 2015, but most recent figures show increasing smolt release, which further supports the 2018 recovery expectation, he said. However, we expect that the new legislation will not allow significant growth relative to 2015 production.

The new regulation allows for a maximum of 3 percent growth in region 10 and 11, and only if biological performance is good, therefore a recovery is possible but further growth beyond this is not. Consequently, after 2018, volume growth In Chile will be limited. “Growth of 2 per cent to 5 percent is possible provided good biological conditions on the farms. In regions 10 and 11, growth will be capped to three percent but could be less if there are biological issues, said Nikolik. In addition, costs are improving in Chile. In the past few years, costs of production increased dramatically in Chile, transforming it from the lowest to the highest cost producer of farmed salmon. Biological costs are the main driver, namely costs related to salmonid rickettsial septicaemia (SRS) and sea lice.

Comparing Norway and Chile, Norway has enjoyed a major advantage in the cost of production in the last few years. However, in the last few months, further lice issues and low harvest weight in Norway, as well as a strengthening of the NOK, have reduced the Norwegian cost advantage from nearly NOK10/kg to just a few kroner. Furthermore, cost expectations are good for Chile, said Nikolik.

The lower biomass in the industry due to the algae bloom has improved the biological conditions, with mortality now dropping well below recent averages, even when excluding the algae bloom effect. Additionally, new medication, especially Pharmaq’s SRS vaccine, is showing promise against the disease that has plagued the industry for many years. “In the next few years, as the vaccine gains acceptance, it may be possible to eliminate the use of antibiotics at approximately $1 per kilo cost,” he said.

Moreover, there are other innovations that will impact the Chilean industry, especially in the field of lice control, where if lice numbers are success fully lowered, costs could decline. “We can conclude that costs in Chile are improving relative to market leader Norway and deem it possible that in future absolute costs will also decline,” said Nikolik.

Although the current high prices for salmon are expected to be supported in the short term, through the first half of 2017, they are expected to decline gradually after that. The analysis does not predict a price crash or a return to low price levels. This is mainly because global supply growth in 2017 and probably in 2018 will still be below long-term demand growth, but also because “the profitable state of Chilean farmers will prevent any panic selling to service debt or pay for feed costs - something we witnessed in 2015.”

The end of the roller coaster

One possible scenario, albeit very hard to predict, is that Chilean volumes will surprise positively in 2018, above Rabobank’s current forecast. This is based on the possibility of improving growth rates due to use of better feed and other productivity boosting inputs made possible by the recent return to profitability. In addition, there will likely be positive effects of the SRS vaccine and other medications on sea lice. All together, these factors could contribute to better fish growth and larger supply growth in 2018 and if this does occur, will likely impact prices. However, this should not impact the profitability margin per kilo of the Chilean farmers, as volume growth due to improving biological performance will also cause cost per kilo to reduce.

“Of course, as always in salmon farming, we cannot rule out unexpected negative events such as algae bloom, volcanic eruptions or social unrest which have impacted the industry in the recent past,” said Nikolik. “However, at least with the end of the El Niño condition – and start of the La Nina – the likelihood of a new algae bloom is far less likely.”

Given these expectations, Nikolik said “with a degree of confidence” that the recent third quarter return to profitability in Chile after virtually two years of losses is set to last and due to the new legislation capping growth to three percent “we do not expect a return of the Chilean rollercoaster.”

-Taken from Intrafish.com, October 2016

A Silver Lining to Chile’s Troubles: A More Automated

Salmon Industry

The industry has embraced more technology to offset some of the dramatic

shifts in supply.

The series of misfortunes that have hit Chile’s salmon industry in the last few years have had one beneficial side effect: the industry has increased automation in several areas, which is helping it compete more effectively on the global stage.

This year’s algal bloom, according to Diego Lages, general manager at Marel Americas, has helped Chilean companies make up their minds that increased automation is worth the investment.

The Icelandic food processing equipment manufacturer sold a fully automated filleting line to a Chilean company - Camanchaca - this year after the bloom, which Lages said is just one of many to come.

“We had to change our entire business performance plan in Chile when the bloom happened,” Lages told IntraFish at a recent Marel ShowHow organized by the company in Copenhagen. We moved completely from a volume driven approach to an efficiency approach.”

There has been a significant increase in machinery sales in Chile as companies move to reduce costs and better utilize their product, he added. “Filleting, trimming, pin bone removal, skinning machinery...all of it is having a great acceptance in Chile now, and it makes sense. You reduce manual labor coasts, and you get more for your fish in less time,” Lages said.

One of the most devastating side effects of the algal bloom were the massive layoffs that resulted from production shortages - an impact that would have been reduced with a more automated system, Lages said. Although manual labor is necessary and Marel is far from achieving complete automation in a plant, investing in high-tech can help companies mitigate the costs of abrupt processing volume changes, he said.

The implementation of technology also helps companies employ specialized staff. “Before, when you needed a technician, you needed someone who could help you, now you need an engineer for example - it helps upgrade labor conditions,” he said.

At the moment many of the major companies in Chile are equipped with Marel solutions, including AquaChile, Australis, Nova Austral, Ventisqueros and Camanchaca. “The market is very different now, Chile’s plans fit perfectly with our lines,” he said.

In addition to reducing costs, the industry is increasingly relying on technology for regulatory reasons, especially traceability. “There is much demand and increasing investment technology in South America, laws regarding traceability are tougher now and it is important for companies to have automated systems,” Stuart McBride, sales and software consultant at Marel, told IntraFish. “Efficient, accurate labeling is one of the drivers for these investments, it becoming clear that this is a necessity.” There is more awareness now from both companies and consumers on the need for transparency and precise label information, he added.

-Taken from www.Intrafish.com, November 2016